Overview

With Sellercloud, you can create a Warehouse Inventory Transfer (WITR) and keep track of your product inventory along the way. The most common scenarios for this feature include seasonal demand, expanding your operations, and space optimizations. Warehouse transfers differ from SKU to SKU Transfers, Physical Inventory Imports, and Product Inventory Adjustments.

Manage Warehouse Inventory Transfers

Sellercloud enables you to easily search for existing Warehouse Transfers, as well as create new ones.

Search WITR

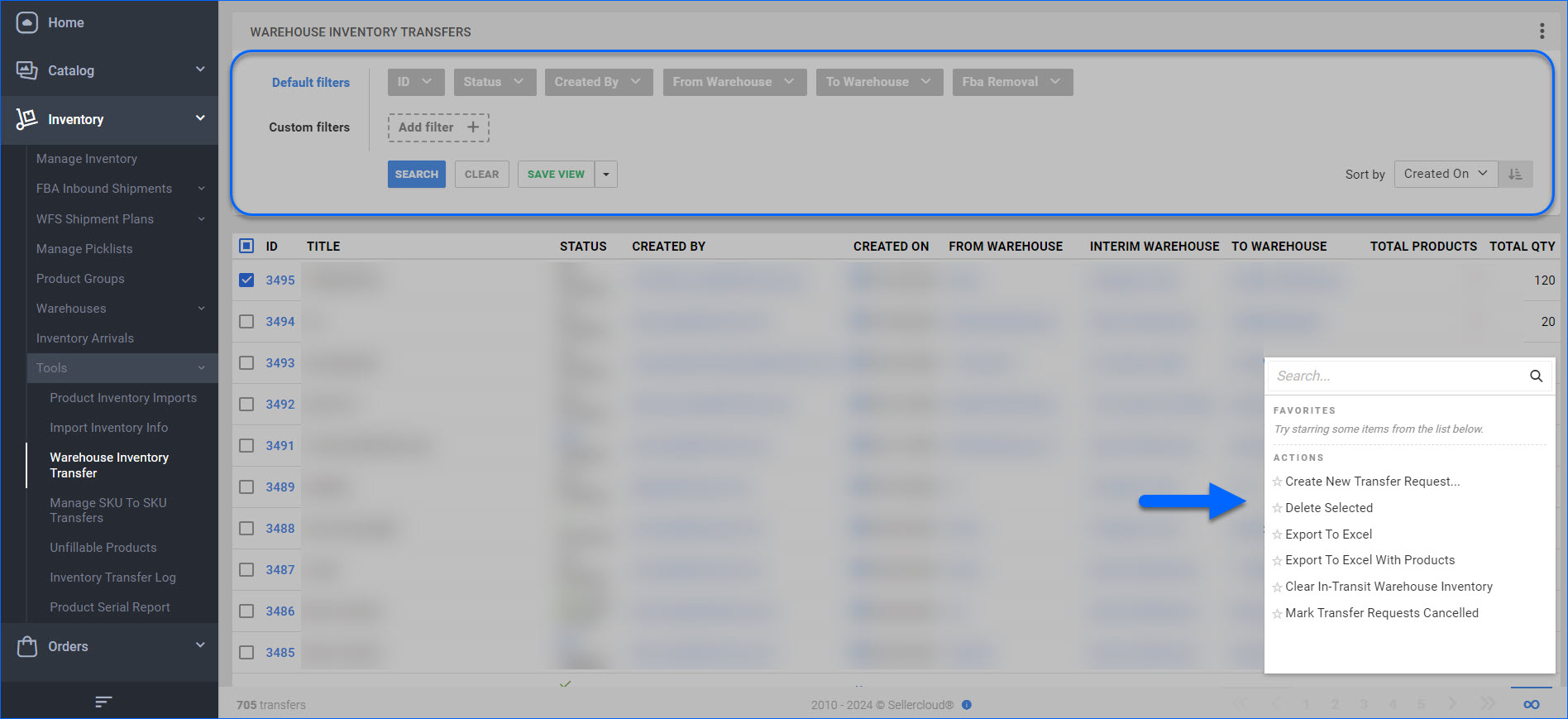

To search Warehouse Transfers, follow the steps below:

- Navigate to Inventory > Tools > Warehouse Inventory Transfer.

- Configure your Default filters to make sure that the results display exactly what you need. The available Default filters are:

- ID

- Status

- Created By

- From Warehouse

- To Warehouse

- Fba Removal

- Optionally, you can add the following Custom filters:

- Company

- Created On

- Created On Date

- Open Status

- Purchaser

- Received On Date

- Requested On Date

- SKU

- Shipped On Date

- Title

- Click Search. Each filter you apply gets highlighted. If a filter is gray or not displayed at all, it’s not active.

- To manage the columns in the grid, click the three dots icon on the top right and select Customize Columns. You can:

- Reorder columns by dragging them up or down in the list;

- Hide columns by clicking the Trash icons;

- Add columns by clicking Add column.

- To arrange the data in a different order, use the Sort by menu.

- To save your filtering and sorting options, click Save view, enter a Name, and click Save.

- Access the Actions menu to:

- Create New Transfer Request

- Delete Selected

- Export To Excel

- Export To Excel With Products

- Clear In-Transit Warehouse Inventory

- Mark Transfer Requests Cancelled

Create WITR

You have 3 options to create WITR requests.

From a Product

To transfer inventory between warehouses for a single product:

- Navigate to Catalog > Manage Catalog > Open a Product.

- Open the Toolbox > Warehouse.

- In the green dialog box, click Transfers > press the Pencil icon at the top right to Edit.

- Click + to add a transfer. Fill in the following fields in the additional window:

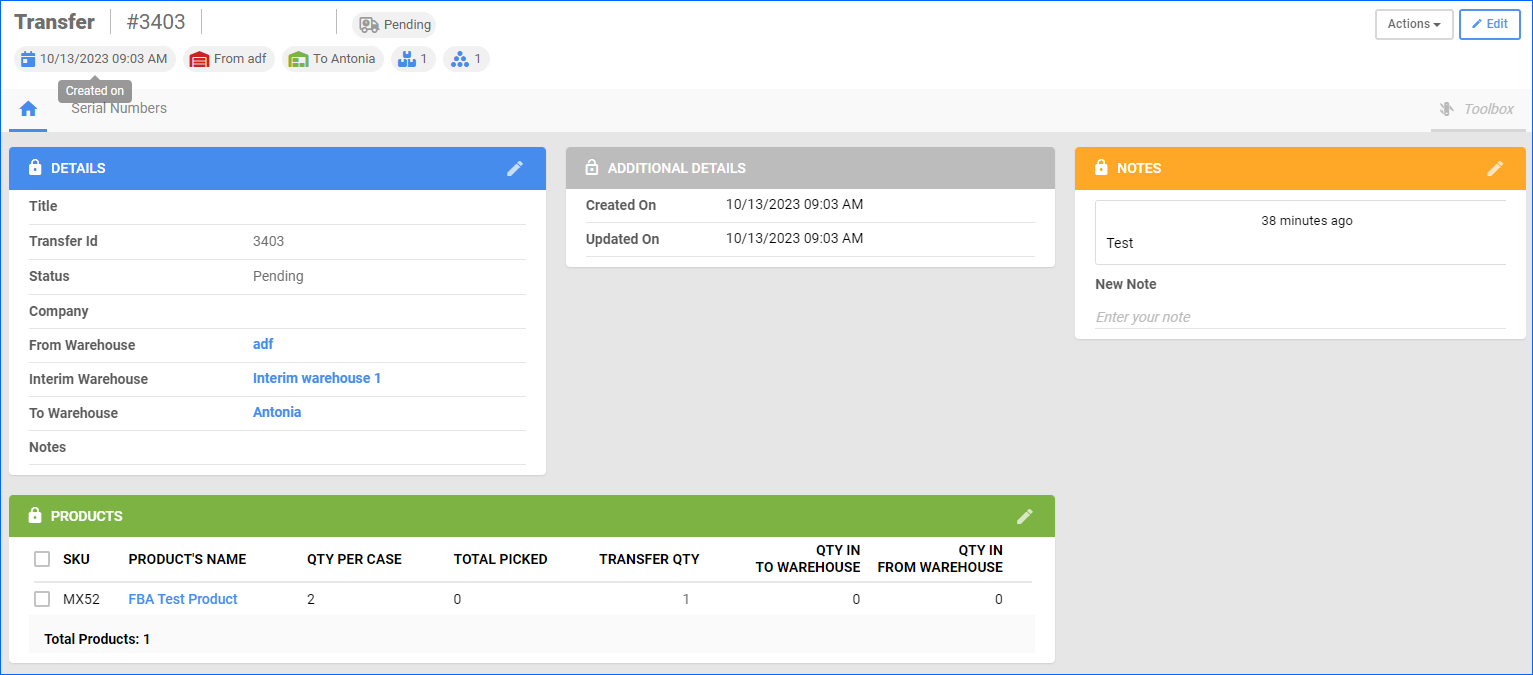

WITR Page

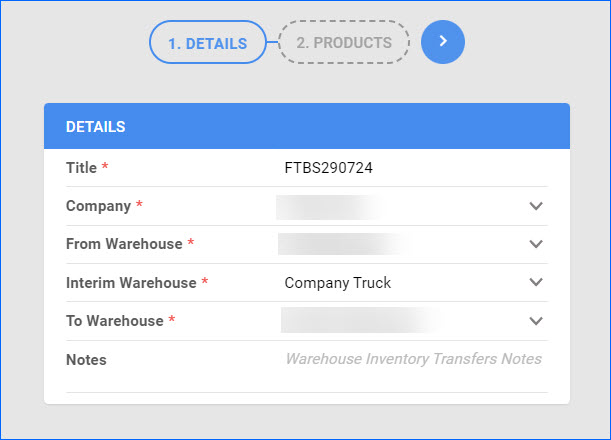

You can also create a transfer from the Warehouse Inventory Transfer page:

- Navigate to Inventory > Tools > Warehouse Inventory Transfer.

- Access the Actions menu at the bottom right of the page and select Create New Transfer Request…

- On the Details page, populate the following fields and click the blue arrow to proceed:

- Title – Name the transfer.

- Company – Select the applicable company.

- From Warehouse – The warehouse from which the products will be shipped.

- Interim Warehouse – An interim location through which the products will be transferred.

- To Warehouse – A destination warehouse where the products will be stored.

- Optionally, add Notes.

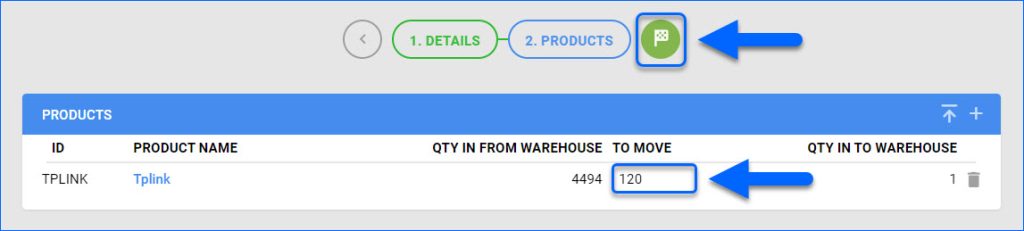

- On the Products page, click the + icon to add products manually or the Upload Products icon to use a file upload. You can also add products and modify quantities later when the request already exists.

- Once the desired products are added, indicate the quantity To move and click the green flag icon to create the transfer.

A pop-up will notify you that the request has been processed successfully. Click View Transfer Details to review it.

Add Products

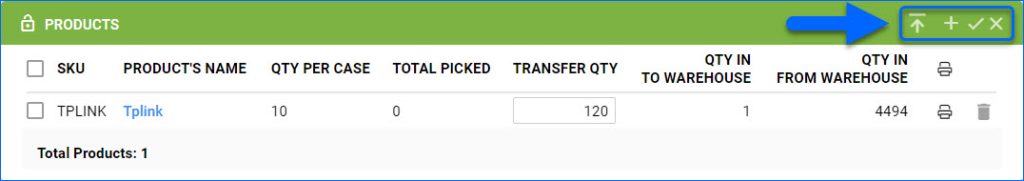

You can easily search for and add products to a Warehouse Transfer Request:

- Open the desired WITR, and click the Edit icon in its Products panel.

- To search for single products, click the + icon and add one or more products separated by a comma in the additional window. Check the box next to each product and click Add Selected to add and continue with the search or Add & Close to add the products and close the window simultaneously.

- When ready, click the Check icon to save the changes.

- Alternatively, click the Upload Products icon to add products in bulk via a file.

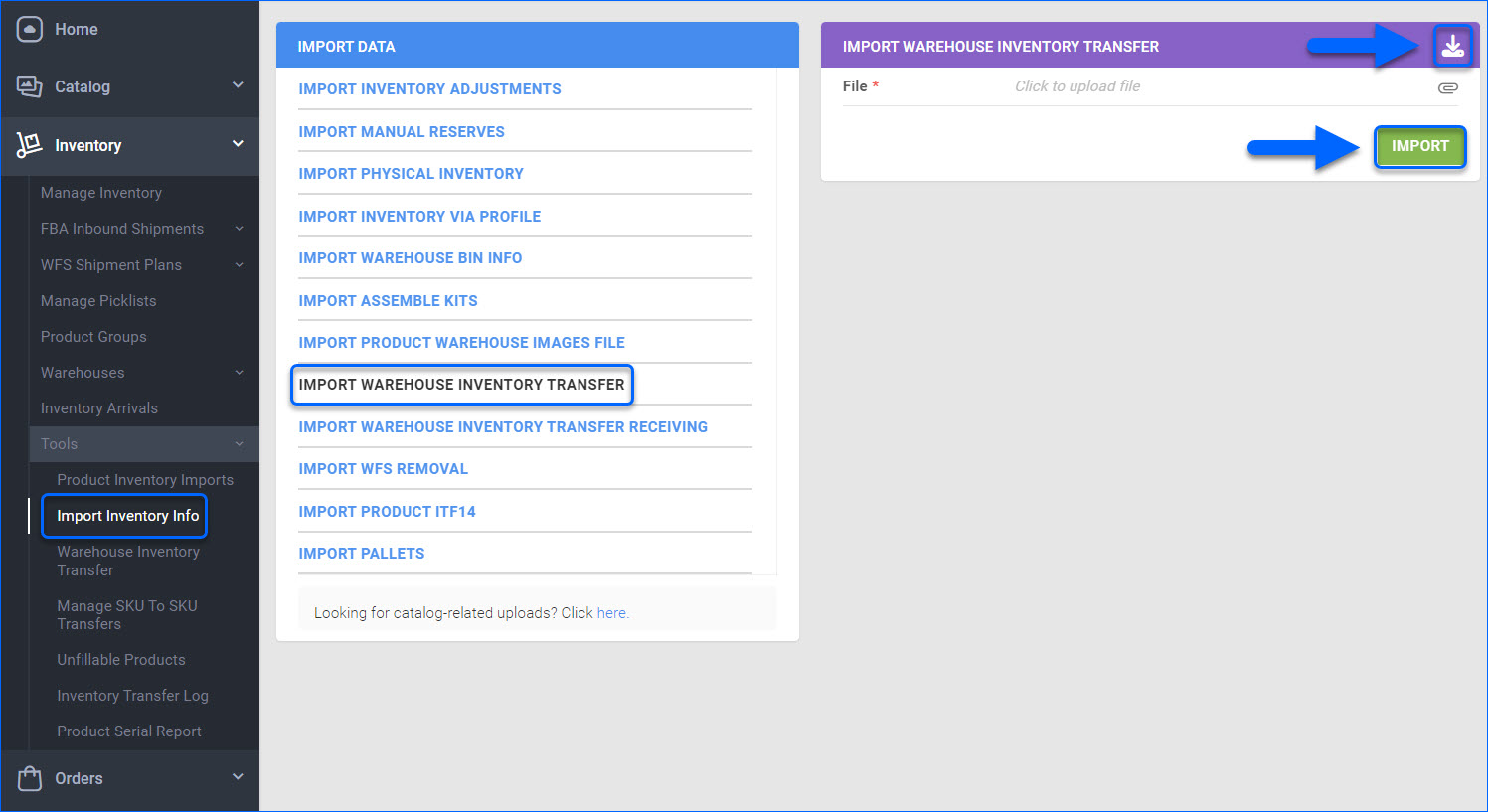

File Import

To upload a WITR import file:

- Go to Inventory > Tools > Import Inventory Info.

- From the import options, select Import Warehouse Inventory Transfer.

- Click the Down Arrow to download the Sample Format.

- Fill in the sheet columns.

- Click the Paper Clip icon to upload a file.

- Click Import.

Process WITR

To complete the workflow and successfully move inventory across warehouses for multiple products at a time, follow the steps below:

- Once you have added products to a WITR, open the Actions menu > Click Set Requested. This will change the status from Pending to Requested. At this stage, we will not move any inventory, but we can reserve it based on a Client Setting. Status Requested will notify your warehouse teams that your inventory is packed and ready to ship.

- Then, from the Actions Menu, click Set Fully Picked.

- When your products ship out, open the Actions menu > Click Set Shipped. At this stage, we will move your inventory to the selected Interim Warehouse.

- To edit transfer quantities, use the Set Unshipped action, update, and use Set Shipped again.

- When products arrive at the destination warehouse, open the Actions menu > Click Set Received. We will transfer the inventory from the interim warehouse to the Final Warehouse you have selected to reflect the movement in Sellercloud.

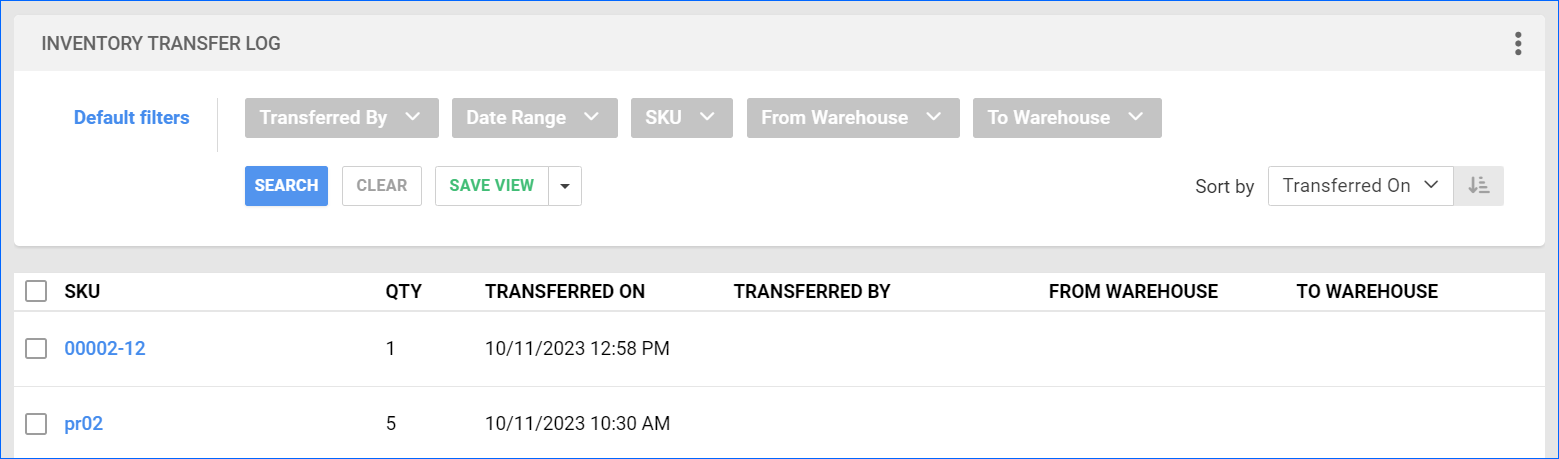

Inventory Transfer Log

For additional visibility, we have a separate page where you can monitor all of your WITR history. We display information about the Product, the Transfer Quantity, and the From and To Warehouses. You can also generate a bulk export file with the action Export to Excel from the Actions Menu at the bottom right.

To reach the page, navigate to Inventory > Tools > Inventory Transfer Log.

Warehouse Inventory Transfer – Additional Functionalities

The WITR workflow offers more functionalities that allow you to customize the process further:

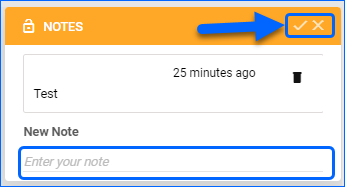

Add Notes

You can keep important details for your warehouse team with notes directly within the transfer request. To add a note, click the Pencil icon in the orange dialog box, enter the information in the New Note field, and click the small Message icon to save the note. If a note is no longer relevant, simply click the Trash Bin icon right next to the message to remove it.

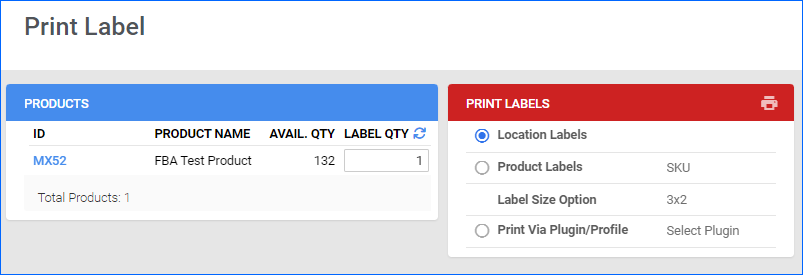

Print Product Labels

To print Product Labels directly through the WITR page, go to Inventory > Tools > Warehouse Inventory Transfer > Search Transfers > Open a Transfer > from the Actions menu, click Print Product Labels. An additional page will appear where you can choose the label format.

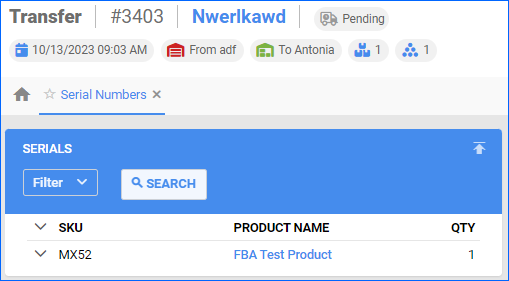

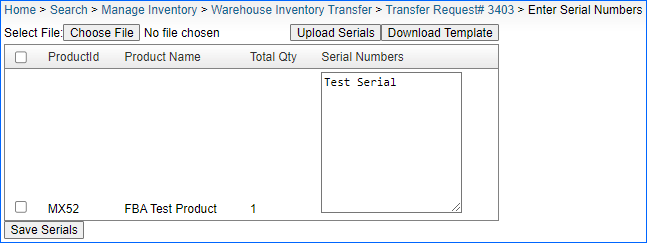

Add Serial Numbers

To add Serial Numbers to products in a WITR, go to Inventory > Tools > Warehouse Inventory Transfer > Search Transfers > Open a Transfer > from the Actions menu, click Select Serial Numbers. You will be redirected to an additional page where you can add multiple serial numbers to each product manually or via file import.

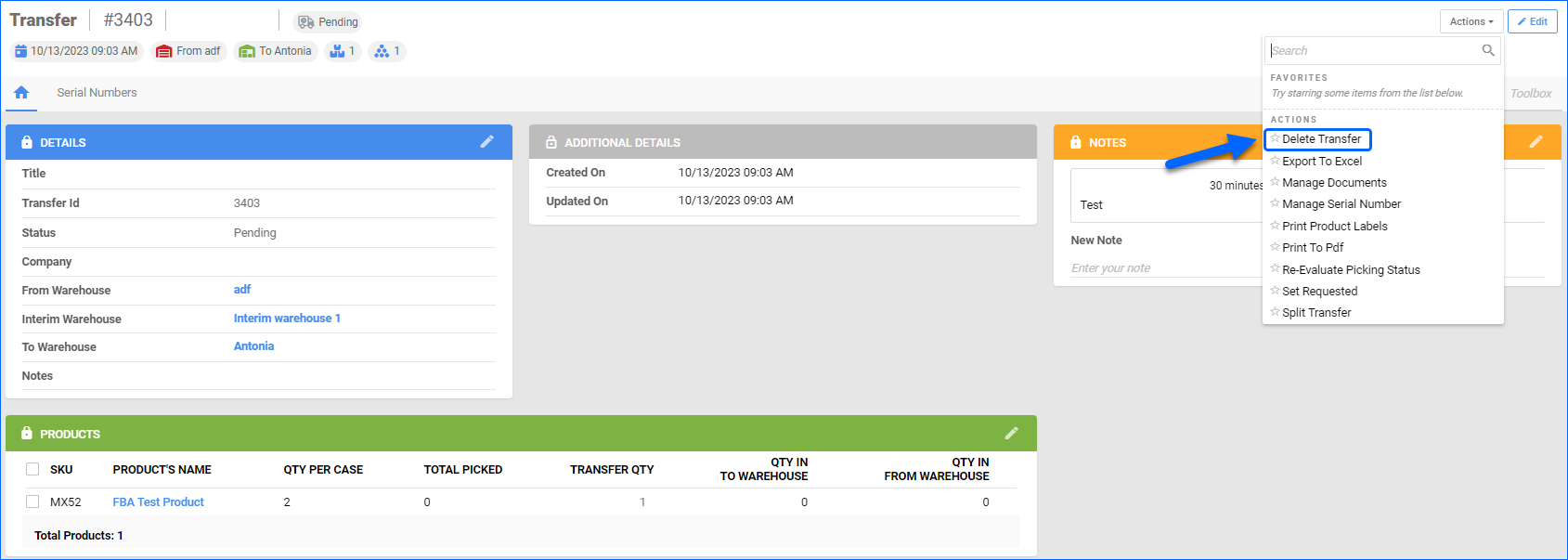

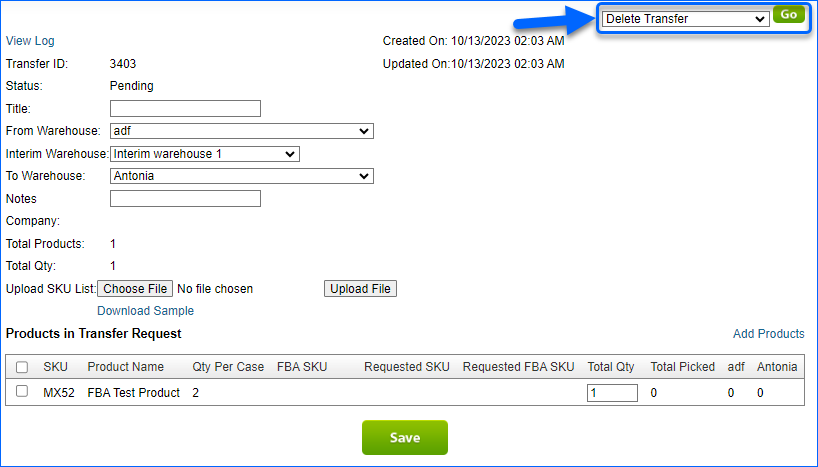

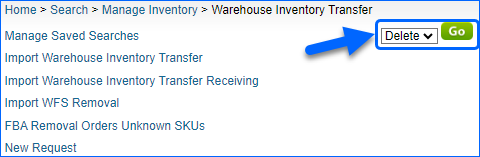

Delete WITR

You can quickly delete WITRs with statuses Pending or Requested. If client settings Enable Warehouse Inventory Transfer Request Reserves and Enable Warehouse Inventory Transfer Request Reserves Exclude Pending Transfer Status are enabled, and you delete a transfer request, we will remove any Product Reserves via a Queued Job and return the inventory back into your aggregate quantity.

You can delete WITRs individually and in bulk:

To remove a single WITR, go to Inventory > Warehouse Inventory Transfer > Open a Transfer > from the Actions menu, click Delete Transfer.

To remove multiple WITRs, go to Inventory > Warehouse Inventory Transfer > Search Transfers > Select Transfers > from the Actions menu, click Delete.

Related Settings

See all relevant WITR Client Settings:

- Allow multiple receivings for warehouse inventory transfer request

-

- If enabled, an additional page will appear when you use the action Set Received. On this page, you can add multiple transfer receivings and edit them at your convenience. If you receive less than the total qty, the transfer will obtain a PartiallyReceived status.

- If disabled, you can enter a value in the Total Received field only once and it will not be editable after you use the action Set Received. To make changes, you must use the action Set Unreceived, change the quantity, and Set Received.

- Allow warehouse inventory transfer from picklist – If enabled, an action called Transfer Between Warehouses will appear in the actions menu of a picklist which will allow you to select products within the picklist and create a transfer request.

- Enable Warehouse Inventory Transfer Request Reserves – If enabled, we will reserve the inventory of products you have added to the request regardless of the transfer status.

- Enable Warehouse Inventory Transfer Request Reserves Exclude Pending Transfer Status – If enabled, we will reserve the inventory of products you have added to the warehouse transfer for all statuses except for Pending. This setting requires Enable Warehouse Inventory Transfer Request Reserves to also be enabled.

- Require PIN To Change Product Inventory Transfer Quantity – If enabled, you will be asked to enter a PIN every time you try to change warehouse inventory transfer quantities.

- Transfer Serial Numbers While Transferring Inventory Between Warehouses – If enabled and you receive a Warehouse Inventory Transfer Request (WITR) for a product, we will also transfer any added serial numbers from the From Warehouse to the Destination Warehouse. This setting can help you preserve the purchasing history.

Overview

With Sellercloud, you can create Warehouse Inventory Transfers (WITR) and keep track of your product inventory along the way. The most common scenarios for this feature include seasonal demand, expanding your operations, and space optimizations. Warehouse transfers differ from SKU to SKU Transfers, Physical Inventory Imports, and Product Inventory Adjustments.

Create Inventory Transfer

Sellercloud gives you the flexibility to create WITR requests in multiple ways:

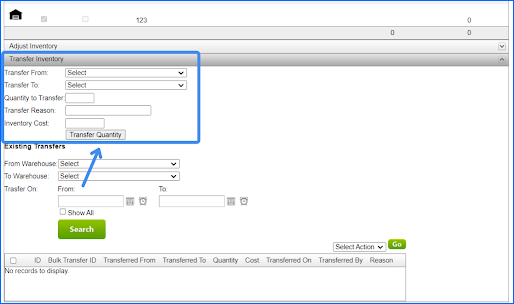

From a Product

To transfer inventory between warehouses for a single product:

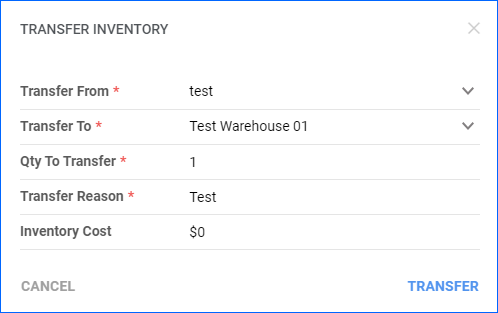

- Navigate to Inventory > Search Products > Open a product > Product Warehouse.

- Scroll down to the bottom of the page and open the Transfer Inventory dropdown.

- Populate the following fields:

- Transfer From and Transfer To warehouse.

- Quantity.

- Transfer Reason.

- Optionally, add Inventory Cost.

- Once filled in, click Transfer Quantity.

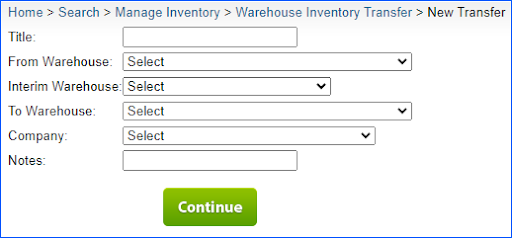

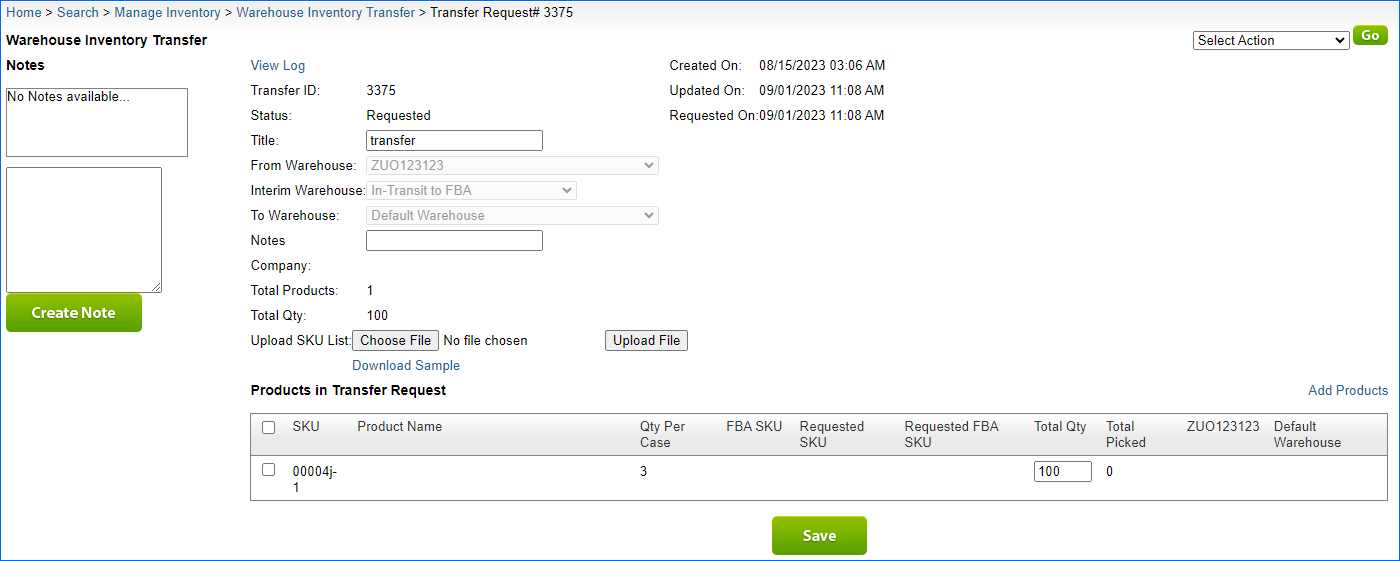

WITR Page

You can also create a transfer from the Warehouse Inventory Transfer page:

- Navigate to Inventory > Warehouse Inventory Transfer.

- To create a new transfer, click New Request.

- On the New Transfer page, populate the following fields:

- Title.

- Company.

- From Warehouse, Interim Warehouse, and To Warehouse.

- Optionally, add Notes.

- Once done, click Continue.

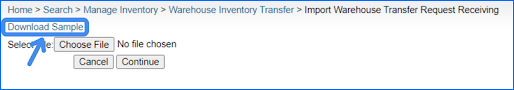

File Import

To upload a WITR import file:

- Go to Inventory > Warehouse Inventory Transfer > Import Warehouse Inventory Transfer.

- Download the Sample File.

- Fill in the sheet columns.

- Click Choose File to upload the sheet.

- Click Continue.

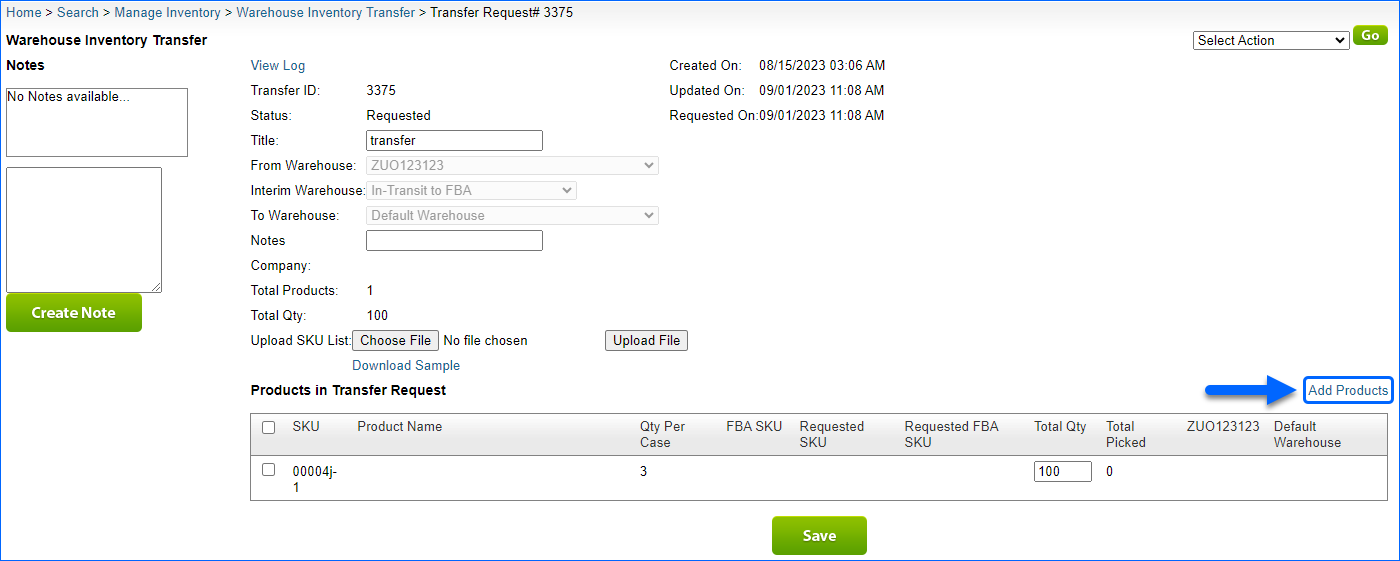

Add Products

You can easily search for products within a WITR and add them to the request:

- On the transfer request, click Add Products. Alternatively, you can upload a file after downloading the sample format and populating the fields.

- In the Add Products to Transfer window, you can use the Search For filter or add multiple products from a sheet by pasting an SKU list and the quantity to add in the textbox.

- Click Add Products or Finish when ready.

Process WITR

To complete the workflow and successfully move inventory across warehouses for multiple products at a time, follow the steps below:

- Once you have added products to the request, open the Actions menu > Click Set Requested > Go. This will change the transfer status from Pending to Requested. At this stage, we will not move any inventory but can reserve it based on a Client Setting. Status Requested will notify your warehouse teams that your inventory is packed and ready to ship.

- Then, open the Action menu and click Set FullyPicked > Go.

- When your products ship out, open the Actions menu > Click Set Shipped > Go. At this stage, we will move your inventory to the selected Interim Warehouse.

- To edit transfer quantities, use the Set Unshipped action, update, and use Set Shipped again.

- When products arrive at the destination warehouse, open the Actions menu > Click Set Received > Go. We will transfer the inventory from the interim warehouse to the Final Warehouse you have selected to reflect the movement in Sellercloud.

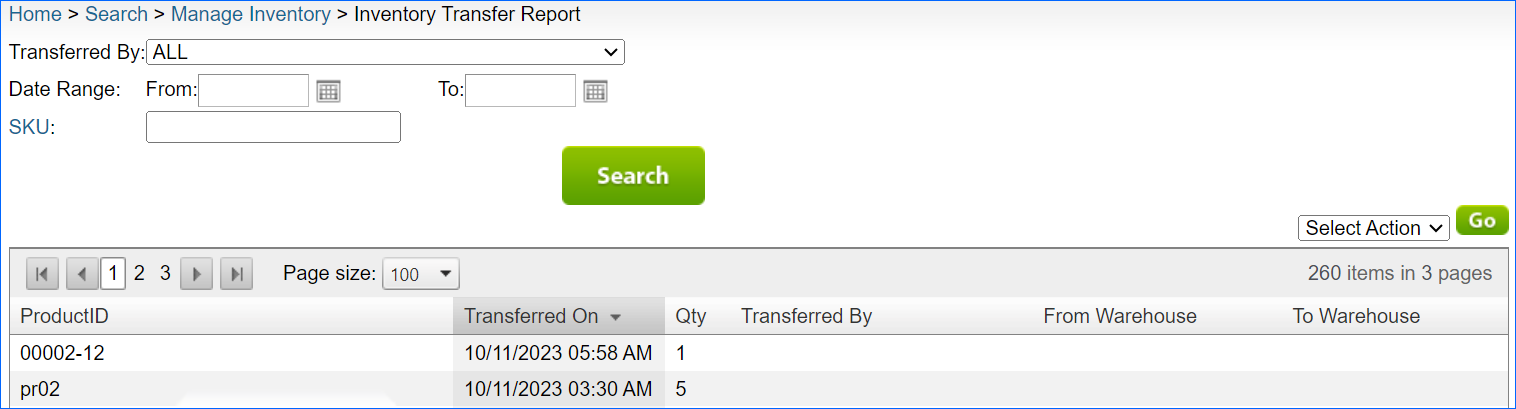

Inventory Transfer Log

For additional visibility, we have a separate page where you can monitor all of your inventory transfer history. We display information about the Product, the Transfer Quantity, and the From and To Warehouses. You can also generate a bulk export file from the Actions menu, click Export > Go.

To access the page, navigate to Inventory > Inventory Transfer Report.

Warehouse Inventory Transfer – Additional Functionalities

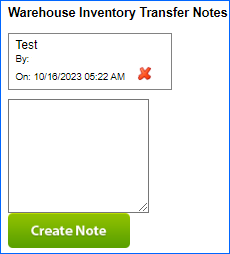

Add Notes

You can keep important details for your warehouse team with notes directly within the transfer request. To add a note, enter the message in the Warehouse Inventory Transfer Notes box and then click Create Note. If a note is no longer relevant, simply click the red X icon right next to the message to remove it.

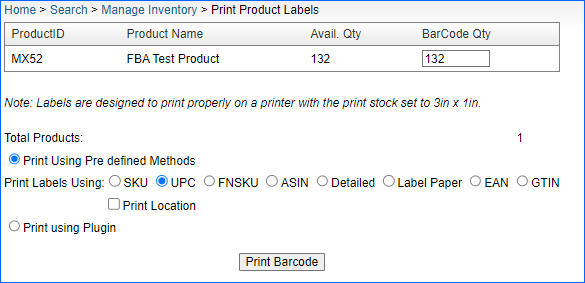

Print Product Labels

To print Product Labels directly through the inventory transfer page, go to Inventory > Warehouse Inventory Transfer > Search Transfers > Open a Transfer > from the Actions menu, click Print Product Labels > Go. An additional page will appear where you can choose the label format.

Add Serial Numbers

To add Serial Numbers to products in a transfer, go to Inventory > Warehouse Inventory Transfer > Open a Transfer > from the Actions menu, click Select Serial Numbers > Go. You will be redirected to an additional page where you can add multiple serial numbers to each product manually or via a file import.

Delete Transfer

You can quickly delete transfers with statuses Pending or Requested. If client settings Enable Warehouse Inventory Transfer Request Reserves and Enable Warehouse Inventory Transfer Request Reserves Exclude Pending Transfer Status are enabled, and you delete a transfer, we will remove any Product Reserves and return the inventory back into your aggregate quantity.

You can delete transfer requests individually and in bulk:

To remove a single transfer, go to Inventory > Warehouse Inventory Transfer > Open a Transfer > from the Actions menu, click Delete Transfer > Go.

To remove multiple transfers, go to Inventory > Warehouse Inventory Transfer > Search Transfers > Select Transfers > from the Actions menu, click Delete > Go.

Related Settings

See all relevant WITR Client Settings:

- Allow multiple receivings for warehouse inventory transfer request

-

- If enabled, an additional page will appear when you use the action Set Received. On this page, you can add multiple transfer receivings and edit them at your convenience. If you receive less than the total qty, the transfer will obtain a PartiallyReceived status.

- If disabled, you can enter a value in the Total Received field only once and it will not be editable after you use the action Set Received. To make changes, you must use the action Set Unreceived, change the quantity, and Set Received.

- Allow warehouse inventory transfer from picklist – If enabled, an action called Transfer Between Warehouses will appear in the actions menu of a picklist which will allow you to select products within the picklist and create a transfer request.

- Enable Warehouse Inventory Transfer Request Reserves – If enabled, we will reserve the inventory of products you have added to the request regardless of the transfer status.

- Enable Warehouse Inventory Transfer Request Reserves Exclude Pending Transfer Status – If enabled, we will reserve the inventory of products you have added to the warehouse transfer for all statuses except for Pending. This setting requires Enable Warehouse Inventory Transfer Request Reserves to also be enabled.

- Require PIN To Change Product Inventory Transfer Quantity – If enabled, you will be asked to enter a PIN every time you try to change warehouse inventory transfer quantities.

- Transfer Serial Numbers While Transferring Inventory Between Warehouses – If enabled and you receive a Warehouse Inventory Transfer Request (WITR) for a product, we will also transfer any added serial numbers from the From Warehouse to the Destination Warehouse. This setting can help you preserve the purchasing history.